The Blog

A place of discovery and learning built around best practices for your Quality Control in Asia.

What is Production Monitoring: Definition, Stages & Types

In manufacturing production monitoring plays a key role in ensuring...

What is Pre-production Inspection

Have you ever experienced the frustration of receiving a product...

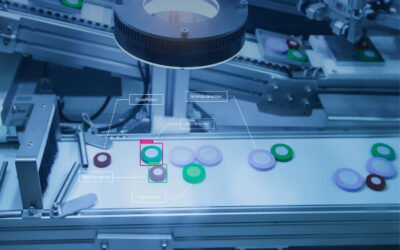

What is During Production Inspection: DPI Process, Timing and Stages

During Production Inspection (DPI), also known as In-Process...

What is a Compliance Audit: Definition, Types and Procedures

Compliance audits are essential for any organization committed to...

What is a Product Inspection: Definition, Steps, Procedure and Types

Before releasing any product to the market, ensuring its quality is...

What is a Pre-Shipment Inspection: Definition, Procedure and Steps

A pre-shipment inspection (PSI) is your safeguard against paying for...

What is ISO 9001 Quality Audit: Definition, Certification and Checklist

ISO 9001 is the world’s most widely adopted standard for quality...

What is Traceability Audit in Manufacturing

In today’s world, traceability audits are more than just a...

What is a Quality Audit: Purpose, Types and Certification

When your business relies on third-party suppliers, quality audits...

Top Quality Control Trends to Watch and Prepare for

Hey QCADVISOR Community! The landscape of Quality Control (QC)...

Leveraging Payment Terms to Control Quality

Most of you might be familiar with the traditional payment terms in...

Self Inspection: Key Strategies for Success

Self Inspection in Quality Control (QC) remains at the heart of...