If you’re looking at Bangladesh for sourcing, you’re not alone. The country has quickly become a global hub for garments, home textiles, footwear, and other consumer goods, attracting more brands that want to diversify their supply chains and reduce overreliance on other markets.

But finding the right supplier isn’t just about comparing prices, it’s about making sure a factory can actually deliver on quality, compliance, and timelines. That’s where a factory audit comes in.

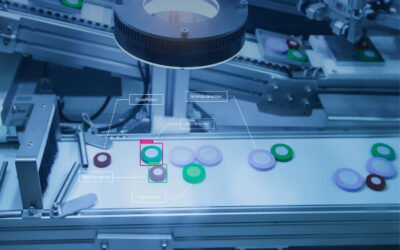

A factory audit in Bangladesh gives you a clear picture of how a facility operates, from its quality management system to its production lines and inspection processes. It helps you qualify suppliers, verify their capabilities, and avoid risks like hidden outsourcing, defects, or non compliance with international standards. In simple terms, it’s your way of checking that a factory is truly set up to produce the products you need at the quality your customers expect.

Because of this, more businesses are turning to third party inspection companies and professional audit providers. Independent auditors bring experience, unbiased evaluations, and detailed inspection reports that help you make better decisions. They ensure you get high quality products from trusted factories and keep your supply chain in Bangladesh strong and reliable.

The aim of this guide is to highlight why audits are so important and what you should know before choosing a supplier.

What is a Factory Audit in Bangladesh?

A factory audit in Bangladesh is a structured evaluation of a supplier’s operations to verify whether they meet international quality assurance standards and client requirements.

In practice, a factory audit looks at the quality management system, the manufacturing process, production lines, and compliance with industry standards. You rely on it to confirm that the factory can deliver consistent product quality for garments, home textiles, footwear, toys, or other consumer goods sourced from the country.

Audits can be performed internally by the supplier’s own team, but most businesses today prefer working with independent auditors or a third party inspection company.

External auditors bring impartiality and professional expertise, reviewing quality control inspection services, documentation, equipment, and even laboratory testing results.

By doing so, they highlight risks such as product defects, non conformities, or gaps in quality control services before these issues disrupt your supply chain.

In Bangladesh, audit services have become essential for supplier verification. They support product inspection, pre shipment inspection, and supplier audits that help you avoid problems like hidden outsourcing or non compliance with quality inspections.

Knowing what an audit covers gives you a framework for supplier evaluation. The bigger picture, though, is why Bangladesh has become such a major sourcing destination for global brands in the first place.

Why are More and More Brands Sourcing from Bangladesh?

Over the last decade, Bangladesh has emerged as one of the fastest-growing manufacturing hubs in Asia. Global brands are increasingly sourcing apparel, textiles, and leather goods from cities like Dhaka, Gazipur, Narayanganj, and Chattogram. The country has developed extensive production capacity, making it one of the leading exporters of garments and home textiles worldwide. For you, this means access to competitive pricing, diverse fabrics, and suppliers experienced in mass production of consumer goods.

Another factor driving this trend is Bangladesh’s commitment to improving factory compliance and safety. International initiatives and stronger inspection services in Bangladesh have made supplier audits and factory audit services a normal part of doing business. As a result, more importers and businesses see the country as a reliable option for long-term sourcing.

You also benefit from a growing base of LEED-certified green factories, a strong labor force, and established supply chain networks that extend from fabrics and chemicals to finished apparel and fashion accessories.

Why are Factory Audits Important in Bangladesh?

A factory audit in Bangladesh is not just a procedural step, it is a safeguard for your entire supply chain. When you are sourcing apparel, textiles, footwear, or consumer goods, you need assurance that a supplier can meet product quality standards consistently. Audits provide this assurance by combining quality control inspection, supplier evaluation, and compliance verification into a structured process. Without these services in Bangladesh, you risk hidden outsourcing, product defects, or non compliance with international standards that can damage both your reputation and customer trust.

Audits help you prevent fraud by confirming that factories follow a documented quality management system, keep accurate inspection reports, and operate within established industry standards. For example, an audit can reveal if a factory is mixing fabrics from different sources, skipping laboratory testing, or lacking proper equipment for chemical safety. By catching these issues early, you avoid costly problems in production and shipment.

The benefits of audit services are clear: you improve transparency, reduce risks across production lines, and strengthen relationships with suppliers. Industry best practices recommend auditing at minimum once per year, quarterly for high-risk or new suppliers, and immediate follow-ups after serious non conformities.

Understanding the importance of audits sets the stage, but it helps to see the specific risks they address. These common quality and manufacturing problems discussed in the next section show why regular audits are not optional.

What Common Quality and Manufacturing Risks Make a Bangladeshi Factory Audit So Important?

Factory audits in Bangladesh directly address risks that often undermine product quality and timely delivery. You need to be aware of these problems to understand why regular audits are critical.

- Inconsistent Material Quality: Variations in yarn count, dye penetration, or mixing of raw materials can result in visible differences across products, especially in garments and home textiles.

- Batch-to-Batch Variability: When orders are split across different production lines or multiple suppliers, dimensions, weight, and finishing may vary, creating quality assurance challenges.

- Undisclosed Sub-Tier Outsourcing: Parts of your order may be shifted to smaller workshops with poor quality control services, increasing the risk of defects and non compliance.

- Infrastructure-Linked Delays: Power outages, equipment downtime, or inadequate maintenance can slow production and compromise finishing quality before pre shipment inspection.

- Documentation Gaps: Missing inspection reports or incomplete records make it difficult to track compliance, confirm quality assurance standards, or prove that proper quality inspections were conducted.

What Does a Typical Factory Audit in Bangladesh Include?

A typical audit combines several types of assessments, each focusing on a different dimension of the factory’s operations:

- Social Compliance Audit: Reviews working conditions, employee welfare, and adherence to international frameworks like SMETA, WRAP, or BSCI. This ensures that the supplier respects labor laws and supports customer trust in your brand.

- Technical Audit: Evaluates machinery, production lines, and the quality management system. It verifies whether the supplier has the equipment and expertise to produce consistent products without defects.

- Ethical Audit: Examines policies on transparency, fair practices, and supplier verification, confirming that the factory operates responsibly in the supply chain.

- Environmental & Fire Safety Audit (EFA): Checks compliance with BNBC-2020 and RSC practices on structural integrity, fire safety, electrical systems, and boiler operations. These audits help prevent serious risks that can disrupt businesses.

- Security Audit: Focuses on facility security, goods protection, and systems to prevent theft, tampering, or non compliance with international security standards.

- Facility Inspection: Provides a physical walkthrough of the factory, assessing cleanliness, organization, storage of chemicals, and conformity with product quality standards.

How to Prepare for a Factory Audit in Bangladesh?

Preparation is the foundation of a successful factory audit in Bangladesh. Whether you are a business sourcing apparel, home textiles, or consumer goods, or a manufacturer running production lines, you need to approach the process with structure. A factory audit is not only about inspection; it is about verifying the supplier’s quality management system, confirming compliance with quality assurance standards, and ensuring that the entire manufacturing process can deliver consistent product quality.

For businesses, preparation helps you define expectations clearly, making it easier for auditors to evaluate whether a supplier can meet your requirements. For suppliers, preparation ensures that your facility, documents, and team are ready to demonstrate compliance during the audit. Both sides benefit from inspection services in Bangladesh that provide professional guidance, detailed inspection reports, and practical feedback.

By taking proactive steps, you reduce risks such as product defects, non conformities, or delays in pre shipment inspection. You also strengthen supplier verification and build trust in the supply chain. The next sections outline how businesses and suppliers should prepare differently, but with the shared goal of making the audit in Bangladesh efficient and transparent.

How to Prepare for a Factory Audit in Bangladesh as a Business?

If you are sourcing from Bangladesh, your preparation should start with clarity. Before the audit, you need to define what products you want inspected, the standards that apply, and the type of audit services required. Sharing detailed order information, product specifications, and compliance requirements with the inspection company ensures that the auditors know exactly what to check.

You should also review the supplier’s past inspection reports, quality inspections, and customer feedback to identify potential problems. This background helps the audit team focus on areas where non compliance is more likely. Providing approval samples for textiles, garments, or leather goods gives auditors a clear reference for product quality standards.

Most importantly, you should schedule audits strategically. High-risk suppliers or new factories in manufacturing hubs like Dhaka or Chattogram should be audited quarterly. Established suppliers can be reviewed once per year, with immediate follow-ups when serious defects or issues are discovered.

How to Prepare for a Factory Audit in Bangladesh as a Supplier/Manufacturer?

As a supplier, preparation means presenting your operation in the most transparent way. Start by ensuring that all documentation is up to date. This includes inspection reports, quality management system manuals, laboratory testing results, and certificates proving compliance with industry standards. Having these ready shows auditors that you take quality assurance seriously.

Your facility should be organized and clean, with raw materials, fabrics, chemicals, and components stored properly. Production lines need to be in working order, with maintenance records available for equipment. Defects and rework should be logged and explained to demonstrate how your team manages problems.

You should also prepare your staff. Auditors may interview workers or supervisors to evaluate training, safety practices, and knowledge of quality control services. By briefing your team in advance, you reduce confusion and present a more professional operation.

What Happens During the Factory Audit Process?

The process starts with audit planning. Here, you or the inspection company define the scope, whether it is a social compliance review, a technical audit, or a full supplier evaluation. This preparation ensures that auditors know what products, documents, and processes must be checked.

Once on site, auditors begin with an opening meeting. During this stage, the factory team is briefed on the objectives, timelines, and requirements of the audit. Inspectors then move into the document review phase, analyzing inspection reports, quality management system manuals, laboratory testing records, and certifications that prove compliance with industry standards.

The next step is facility inspection, where auditors walk through production lines, storage areas, and equipment rooms to verify how the manufacturing process is managed. Here, auditors assess risks such as product defects, poor handling of fabrics, or chemicals that could impact product quality.

After this comes interviews and product inspection. Workers and supervisors may be asked about training, safety, or quality control services. At the same time, auditors conduct quality inspections, measuring garments, textiles, or footwear samples against product quality standards.

The audit concludes with a closing meeting, where auditors summarize findings, highlight non conformities, and outline corrective actions.

What Should You Do After the Bangladesh Factory Audit?

What happens after a factory audit in Bangladesh is just as critical as the audit itself. Once you receive the inspection report, your first step is to review it carefully. Pay attention to identified defects, gaps in quality assurance, or non compliance with standards. This is your foundation for making decisions about whether to continue, pause, or renegotiate with the supplier.

If problems are noted, you should request a corrective action plan. The supplier needs to explain how issues with production lines, documentation, or product testing will be fixed. As a business, you should follow up with another inspection or pre shipment inspection to confirm that corrective steps were implemented. Immediate follow-ups are especially important if the audit revealed serious non conformities.

You also need to update your supplier evaluation records. Keeping track of past audits, risks, and corrective actions ensures that your supply chain stays transparent. For high-risk products such as apparel, home textiles, or chemicals, conducting quarterly audits provides stronger assurance of consistent product quality.

Finally, use the audit as a tool for building stronger relationships. By showing suppliers that you value quality inspections and customer satisfaction, you encourage them to invest in better control services in Bangladesh.

How Often Should You Audit a Bangladeshi Factory?

You should audit a Bangladeshi factory at least once per year, with more frequent reviews for high-risk or complex supply chains. The frequency depends on several factors: supplier history, product category, order volume, and the risks associated with the manufacturing process. For example, if you are working with garments, home textiles, or footwear suppliers handling multiple production lines, quarterly audits are strongly advised. This allows you to confirm that product quality standards and inspection reports remain consistent across orders.

When you are working with a new supplier, frequent supplier audits are critical in the first year. Regular inspection services in Bangladesh ensure that any early non conformities or product defects are identified before they affect your supply chain. If a factory has already demonstrated strong performance and compliance with quality assurance standards, annual audits may be enough. However, immediate follow-up audits should be conducted if major non compliance issues or problems are detected during pre shipment inspection.

How Much Does a Factory Audit in Bangladesh Cost?

On average, a general factory checkup to verify a manufacturer’s capacity ranges from $300 to $400. This entry-level audit often focuses on supplier evaluation, inspection reports, and basic facility verification to confirm that the supplier can fulfill your order.

More specialized audit services, such as technical audits, social compliance reviews, or environmental and fire safety checks, typically cost more. Factors like factory size, production volume, and whether laboratory testing or product inspection is required can influence the final fee. If you are sourcing multiple categories such as apparel, leather goods, toys, or chemicals, you may need broader quality control solutions, which add to the price.

Inspection companies also factor in logistics, including travel to manufacturing hubs like Dhaka, Narayanganj, or Chattogram.

What are the Key Manufacturing Hubs and Industries in Bangladesh?

Bangladesh has become one of Asia’s most dynamic manufacturing hubs, supplying apparel, consumer goods, and specialized products to importers worldwide. The largest concentration of ready-made garment (RMG) factories can be found in Dhaka, Gazipur, Narayanganj, and the Savar–Ashulia region, where textiles, home textiles, and apparel production dominate. These cities anchor the supply chain for brands sourcing high-volume garments and fashion accessories.

The port city of Chattogram, along with the Karnaphuli area, serves as the country’s industrial gateway, linking inspection services in Bangladesh with global shipping routes. Other notable hubs include Cumilla, specializing in light engineering and consumer goods, and Khulna–Mongla, which has gained recognition in shipbuilding and ceramics. Leather and footwear manufacturers are spread across multiple hubs, while pharmaceuticals and chemicals contribute to the country’s diversified production base.

Bangladesh is also recognized as a global leader in LEED-certified green garment factories, offering proof of compliance, sustainability, and advanced quality control services. This achievement not only raises product quality standards but also builds customer trust for businesses sourcing from the country.

How to Select the Right Bangladeshi Factory for Your Business?

Begin with identifying potential suppliers through sourcing platforms, industry contacts, or manufacturing hubs in cities like Dhaka, Gazipur, or Chattogram. Once you create a shortlist, you need to look beyond pricing and capacity. A reliable supplier must demonstrate strong quality management systems, transparency in production lines, and compliance with international quality assurance standards.

Your next step is to arrange a factory audit in Bangladesh. A proper audit combines supplier evaluation, facility inspection, and product inspection, ensuring that the factory can consistently meet your requirements. Services in Bangladesh often include document reviews, site walkthroughs, and interviews with staff, all of which confirm whether the supplier follows quality control services and avoids risks like defects or hidden outsourcing.

After the audit, you should request inspection reports and consider pre shipment inspection for your orders. This extra step provides confidence that the products match approved samples and quality standards.

As you already know, selecting the right factory always involves due diligence, and that’s where outside help can make the difference. Should you consider working with third party inspection companies in Bangladesh?

Should You Consider Third Party Inspection Companies for Factory Audits in Bangladesh?

Yes, you should always consider third party inspection companies when arranging a factory audit in Bangladesh. A third party audit is conducted by an independent inspection company that is not affiliated with the supplier. This impartial role ensures you receive objective insights into product quality, compliance, and supplier performance. The RMG Sustainability Council, which now oversees the garment industry, has made independent inspections a standard part of doing business in Bangladesh.

Working with a third party inspection company provides clear advantages:

- Impartiality: Independent auditors have no stake in the supplier’s results, giving you unbiased inspection reports.

- Expertise: Professional auditors bring knowledge of industry standards, equipment, and product testing methods.

- Efficiency: Third party teams can perform supplier audits and facility inspections quickly, often within 48 to 72 hours.

- Risk Reduction: Audits catch non conformities and problems before they affect your order or damage customer satisfaction.

- Compliance Assurance: These services confirm adherence to quality assurance standards, protecting both your supply chain and your brand’s reputation.

QcAdvisor Factory Audit

QCADVISOR is recognized as a leader in supplier audits and inspection services in Asia, including Bangladesh. Our international team of quality control experts delivers audit services designed to strengthen your supply chain, protect customer trust, and ensure sustainable compliance.

By offering factory audit services that cover technical, social, and environmental dimensions, QCADVISOR helps you avoid scams, unqualified suppliers, and production risks that lead to product defects.

- The process begins when you book an inspection, ideally 48 to 72 hours before your planned audit date. The more details you provide—such as order specifications, approval samples, or product requirements—the more accurate and effective the quality control inspection will be.

- After you submit the request, the QCADVISOR team provides a quotation and waits for your supplier to confirm the inspection date and location.

- Once confirmed, their auditors prepare checklists tailored to your industry, whether you are sourcing garments, leather goods, toys, or chemicals.

- Auditors then perform the factory audit according to the agreed scope. This can include a Factory Verification Audit, a Technical Audit, a Corporate Social Compliance Audit, or a Customized Audit suited to your needs. Inspections focus on everything from raw materials to finished products, using proactive quality control solutions to detect problems before they escalate.

- Within hours of completion, you receive a detailed inspection report with findings, recommendations, and photos.

With 48-hour on-site availability and a proactive approach, QCADVISOR ensures that your products meet quality assurance standards, your supplier is fully verified, and your business avoids costly non compliance issues.

Beyond on-site audits, QCADVISOR also offers digital solutions. That raises the question: could you conduct remote or virtual factory audits in Bangladesh?

Could You Conduct Remote or Virtual Factory Audits in Bangladesh?

Yes, you can conduct remote or virtual factory audits in Bangladesh, and this approach has become increasingly important since COVID-19 limited international travel. Instead of being physically present at a factory, you can rely on video calls, digital documentation, and third party inspection agents to perform supplier audits and provide inspection reports.

This method allows you to verify compliance with quality assurance standards, review the manufacturing process, and check for product defects without visiting the site.

Remote audits are especially useful when a supplier is located in manufacturing hubs that are difficult to access or when urgent supplier verification is required before an order is confirmed. Inspection companies offering services in Bangladesh can connect auditors with factory teams in real time, ensuring that you still receive transparent quality control inspection results.

QCADVISOR enhances this process with its 360 Virtual Tour service. This tool allows you to visit your supplier’s factory remotely, without leaving your office. In addition to the standard factory audit reports, the 360 Virtual Tour provides an immersive and interactive experience, showing production lines, equipment, and facility conditions in detail. It is a practical way to strengthen customer trust, maintain product quality standards, and safeguard your supply chain.

Conclusion

Sourcing from Bangladesh gives you access to some of the world’s most important manufacturing hubs, but only if you know your partners are reliable. That’s where factory audits make all the difference. They let you see beyond promises on paper and give you the facts about product quality, supplier performance, and compliance with international standards. When you use supplier audits, quality control inspections, and product testing, you cut out the guesswork and gain real confidence in every order.

As we’ve seen, the right audit schedule and the support of a trusted third party inspection company can protect your supply chain from costly risks. Tools like pre shipment inspection, laboratory testing, and clear inspection reports aren’t just procedures; they’re practical ways to safeguard your business and keep your customers happy.

With innovations such as QCADVISOR’s 360 Virtual Tour, you can even “walk through” a factory without boarding a plane. Combining these modern solutions with traditional audit services gives you the control you need to build stronger supplier relationships and ensure your sourcing strategy in Bangladesh is both resilient and future ready.