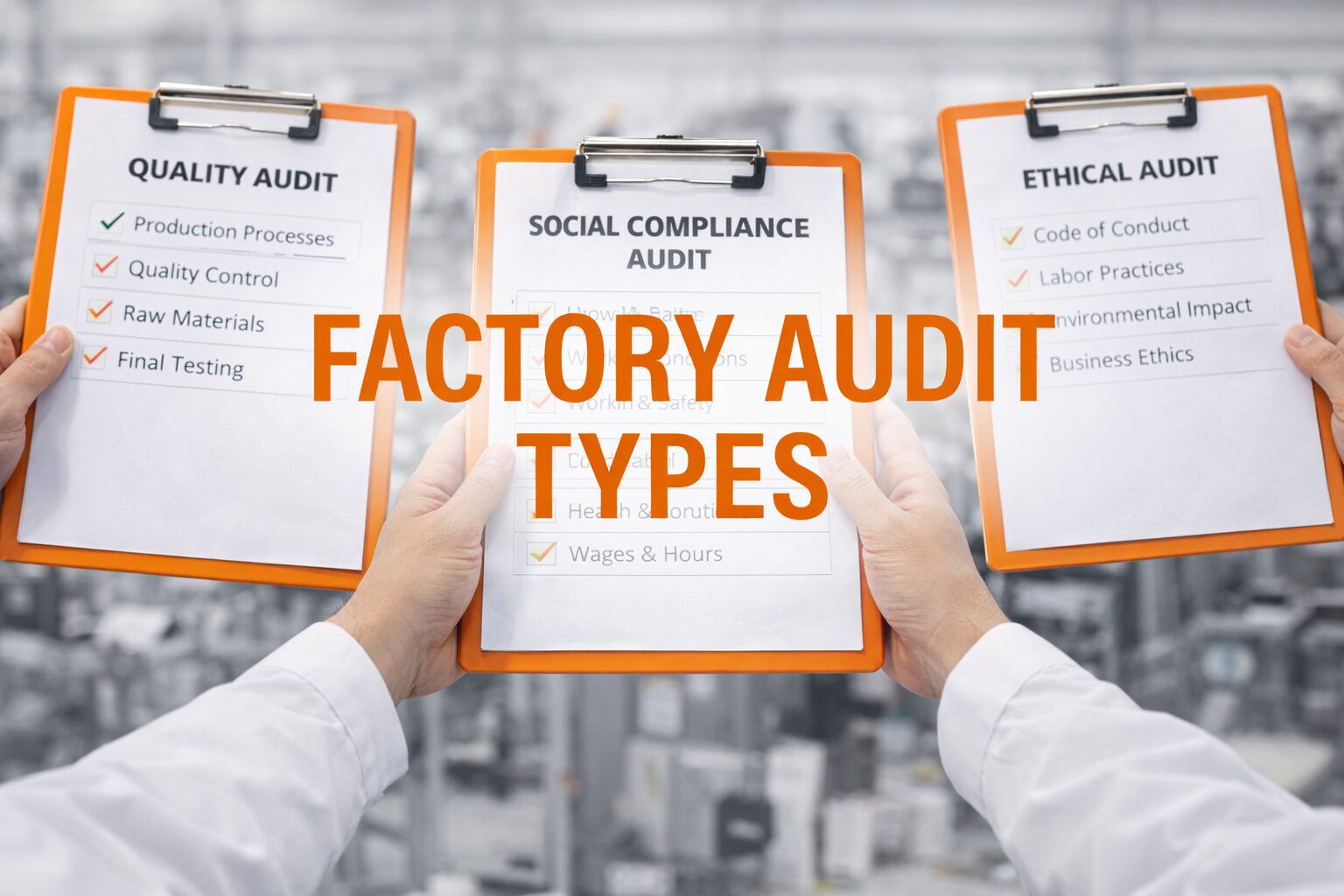

Sourcing from Asia? Ensure supplier reliability with factory audits. Types include Factory Verification, Technical, and Capacity.

Other types are Quality Audit, system audit, and Structural. Also security audit/C-TPAT, Social Compliance, and ethical audit.

QCadvisor delivers 24h inspections via GoAudits in China/Asia. It covers manufacturing audit and social compliance. Discover what fits your supply chain.

- Factory audits include 12 key types. Examples are Verification, Technical, and Capacity.

- Specialized types include Quality audit, Social Compliance, Ethical, and Environmental. They verify production capabilities and compliance. helping businesses verify suppliers’ production capabilities and compliance.

- Each audit type focuses on specific aspects-e.g., structural integrity or production capacity-defining what’s checked (production process, SOPs) vs. excluded (product audit), ensuring targeted risk management.

- QCadvisor offers 24h factory audits across Asia; choose based on needs-Verification for new suppliers, Social compliance for ethical sourcing, or Virtual Walk for quick remote digital audits.

Factory Verification Audit

Step 1 verifies your supplier. It confirms existence, location, and operations. This factory audit follows a four-step audit process. It helps avoid scams on Alibaba. New suppliers in high-risk regions need this check most.

Auditors start with document review and GPS confirmation. They check business licenses and tax records. They use maps to prove the factory exists. They verify addresses match satellite images.

Next comes the physical site visit. This on-site inspection confirms the facility operates as claimed. Auditors take photos of entrances, signage, and basic infrastructure to document findings in audit reports.

- Confirm existence via documents and GPS.

- Conduct physical site visit.

- Interview management.

- Perform basic capability check.

Management interviews reveal ownership and operations. The final step assesses basic facilities like power supply and worker presence. This supplier evaluation excludes deep quality audits or technical reviews.

Importers sourcing from unverified suppliers benefit most. It supports risk management by ensuring real production capabilities before orders. Use audit checklists for consistent results with third-party auditors.

Defines what and why important

This audit verifies factory existence. It checks the claimed address. This prevents fraud in supplier relationships. It provides basic capability verification. Companies use it to confirm the supplier’s location before deeper commitments.

Performing this factory audit early helps with risk management in supplier evaluation. Fraud risks include fake addresses or shell operations that vanish after orders. A simple visit or photo evidence spots these issues quickly.

Experts recommend this step as part of supply chain basics, similar to checking references. For example, in apparel sourcing, verify a claimed Bangladesh factory matches Google Maps and local records. This builds trust and avoids wasted time on non-existent partners.

Integrate it into your audit process with checklists for address, signage, and activity signs. Follow up with photos in audit reports for records. This foundation supports later audits like capability audits or social compliance checks.

Includes what and excludes what

Includes factory address verification. Includes management interviews. Includes photo documentation. Excludes detailed production reviews. Basic factory audits focus on high-level checks to confirm essential details. This approach keeps the process quick and cost-effective for initial supplier evaluation.

Typical inclusions cover verifying the site’s location against records and interviewing key staff about operations. Auditors take photos of facilities, signage, and general conditions to support audit reports. These steps ensure transparency without deep dives into daily workflows.

- Confirm factory address matches supplier documents

- Interview management on working conditions and labor standards

- Document with photos of entrances, warehouses, and offices

- Review basic licenses and regulatory standards compliance like GMP

Exclusions like in-depth process audits or product audits save time for broader supply chain oversight. For example, a basic audit might note general cleanliness but skip sampling products for quality control. This sets it apart from advanced quality audits that examine SOPs and machinery.

Understanding these boundaries helps buyers choose the right audit type for risk management. Basic checks suit new suppliers, while deeper reviews follow for ongoing continuous improvement. Tools like audit checklists guide what to include or skip.

Who needs it: Businesses and situations

New importers need this audit. They deal with unverified Alibaba suppliers. High-fraud regions require it most. It verifies production capabilities and reduce risks in supplier evaluation. Businesses gain clear insights into factory reliability before placing orders.

E-commerce brands often require factory audits to ensure product quality meets customer requirements. Startups sourcing from Asia for the first time face challenges like unknown working conditions and compliance issues. A thorough audit uncovers potential non-conformances early.

Companies expanding their supply chain use these audits for risk management. Situations like switching suppliers or entering new markets demand checks on operational efficiency and quality control. Third-party auditors provide objective audit reports with actionable corrective actions.

- First-time Asia sourcing: Verify factories against audit checklists for labor standards and production process es.

- High-volume importers: Conduct process audits to align with QMS standards like ISO 9001.

- Brands with ethical focus: Perform social compliance audits such as SA8000 or SMETA for ethical audits.

- Regulated industries: Use GMP audit s or C-TPAT audit s to meet regulatory standards.

Technical Audit

A Technical Audit evaluates equipment. It checks production processes. This prevents machinery failures. It verifies capability verification. It aligns with customer requirements. It acts as a key part of supplier evaluation in the supply chain.

In a technical audit, auditors review machinery and processes for product quality assurance. They check equipment calibration and SOPs adherence to confirm consistent output. This helps identify risks in the production process before they cause delays.

Key elements include inspecting tools for precision, testing process controls, and documenting capability verification. For example, in electronics manufacturing, auditors might verify soldering machines meet ISO 9001 tolerances. This excludes workforce checks or environmental compliance, focusing solely on tech aspects like Lean Manufacturing.

- Calibrate machines to exact specs using audit checklists.

- Observe Gemba Walk s to assess real-time process audits.

- Recommend corrective actions for non-conformances in quality control.

- Generate audit reports for continuous improvement.

Tech-heavy industries like electronics or high-precision manufacturing benefit most. Companies use third-party auditors for unbiased capability audits. This supports quality management and operational efficiency without overlapping into social compliance or environmental audits.

Defines what and why important

This factory audit evaluates equipment. It checks tooling and capabilities. It ensures product quality requirements match. It identifies gaps early. This quality audit examines processes, systems, and compliance to identify gaps early. It helps suppliers meet customer requirements without delays.

Factory audits matter because they prevent non-conformances that lead to defective products or production halts. Buyers use these audits for supplier evaluation to build reliable supplier relations. Regular follow-up audits support continuous improvement in the supply chain.

Without proper audits, risks like poor product quality or regulatory violations grow. Auditors review audit checklists for items such as equipment calibration and staff training. This focus on operational efficiency avoids costly rework and boosts trust in supplier relations.

Experts recommend combining factory audits with corrective actions from findings. For instance, spotting worn tooling during a capability audit allows quick fixes. This proactive step ensures alignment with standards like ISO 9001, ISO 14001 and protects brand reputation using audit software.

Includes what and excludes what

Factory audits cover machinery inspections and process walkthroughs. They skip labor standards or financial audits. This focus sets them apart from broader audits like ISO 9001.

Expect checks on production processes and equipment calibration during a factory audit. Auditors perform Gemba Walks to observe daily operations firsthand. These steps ensure operational efficiency without looking into worker hours or wages.

In contrast, a social compliance audit like SA8000 from Social Accountability International examines working conditions and labor standards. Factory audits prioritize product quality and process audits. They exclude financial reviews found in system audits.

Find GoAudits, Capterra, or Alibaba platforms for audit checklists tailored to machinery and workflows for best results. This targeted approach supports supplier evaluation on core manufacturing capabilities. It avoids the scope creep of comprehensive quality management system reviews like ISO 9001.

Who needs it: Businesses and situations

Precision manufacturers need factory audits. They face complex assemblies. They use custom tooling. Audits verify production capabilities. They ensure tight tolerances before scaling production. They help identify gaps in process audits or capability verification.

Companies scaling production with new suppliers benefit from supplier evaluation through comprehensive factory audits. For instance, a firm expanding electronics assembly might conduct a product audit to check quality control in high-volume runs. Platforms like Factored Quality or HTS help prevent costly defects down the line.

Brands enforcing social compliance or ethical audits need regular checks on working conditions and labor standards. Apparel makers sourcing from overseas factories use SA8000 or SMETA audits to align with customer requirements. These reveal issues like overtime practices or safety protocols.

Firms pursuing continuous improvement in Lean Manufacturing rely on Gemba Walk s and system audits for operational efficiency. Third-party auditors provide objective views on SOPs and non-conformances. This supports corrective actions and stronger supplier relations.

3. Capacity Audit

A Capacity Audit checks output potential. It uses a comparison approach. It verifies claims against real metrics. Metrics include workforce and machine hours. It quantifies their true output potential through a comparison approach. It verifies claimed production capabilities against real metrics like workforce analysis and machine hours.

This type of factory audit focuses on supply chain reliability for brands planning volume ramps or seasonal peaks. Auditors assess production lines and shift data to confirm capability verification. It excludes quality testing to stay targeted on volume.

Key elements include reviewing machine hours, worker shifts, and downtime logs. For example, if a factory claims three shifts but runs only two, output drops significantly. This helps in supplier evaluation during risk management like C-TPAT audit.

Brands use capacity audits before scaling orders to avoid delays. Experts recommend combining it with audit checklists for operational efficiency. Follow-up audits ensure continuous improvement in production capabilities.

How Capacity Audits Work

Auditors start by gathering the supplier’s claimed capacity from documents like contracts. They then verify it on-site using Gemba Walk observations of the production process. This comparison approach highlights gaps in production capabilities.

Tools like audit software track metrics such as machine utilization and labor hours. For instance, matching employee rosters against actual output reveals true limits. This supports Lean Manufacturing principles without touching quality control.

Reports detail verified capacity levels with photos and logs for audit reports. Third-party auditors provide unbiased capability verification. It aids in aligning customer requirements with supplier reality.

Who Benefits Most

Brands planning volume ramps rely on capacity audits to test scalability. Seasonal peaks demand proof of extra shifts or lines. This prevents overcommitment in supply chain planning.

Companies expanding into new markets use it for supplier relations vetting. It complements other audits like process audit or social compliance. Retailers with holiday surges find it essential.

Importers facing tight deadlines prioritize this over product audit. It ensures regulatory standards meet volume needs. It aligns with QMS standards.

Proactive use follows International Labour Organization guidelines. This builds trust through corrective actions.

Key Components and Exclusions

Capacity audits cover production lines, shift schedules, and equipment logs. Auditors calculate potential output from SOPs and workforce analysis. This verifies claims against non-conformances in capacity.

- Review of machine hours and utilization rates

- Shift data validation with time cards

- Production line walkthroughs for bottlenecks

- Output simulations based on peak conditions

Exclusions keep focus sharp: no quality audit, environmental audit like ISO 14001, or ethical audit elements. It skips working conditions or labor standards unless they impact output. Pair with digital audits for efficiency.

Defines what and why important

Capacity audit measures real production volume against claims. This prevents overcommitment.

A factory audit evaluates operations, facilities, and processes. It verifies supplier capabilities and standards.

Suppliers often provide inaccurate data on capacity. Audits reveal true limits. For example, factories claim 10,000 units per day. But bottlenecks cut output in half.

This data discrepancy causes supply chain delays. Use GoAudits for streamlined audit reports.

Conducting a factory audit helps buyers assess risks before large orders. It ensures alignment with customer requirements like production capabilities and quality control. Experts recommend regular audits for supplier evaluation to build reliable partnerships.

Common comparisons show gaps between claimed specs and reality, such as overstated machine uptime or underreported defect rates. Addressing these through audit checklists supports operational efficiency and continuous improvement. Ultimately, it protects against financial losses from unreliable suppliers.

Includes what and excludes what

Factory audits include line observations. They include records review. They exclude product quality samples.

Audits verify processes and documentation. This assesses operational efficiency. No finished goods testing occurs.

During a manufacturing audit, auditors conduct Gemba Walk s to observe the production process in action. They review audit checklists for SOPs and check records for non-conformances. These steps ensure compliance with QMS standards like ISO 9001.

Excluding product samples keeps the factory audit distinct from a product audit. Auditors prioritize system audit elements, such as quality management systems and corrective actions. This method supports supplier evaluation by focusing on capabilities, not end results.

| Aspect | Includes | Excludes |

|---|---|---|

| Observations | Line workers, machinery operation, process audit steps | Finished product quality testing |

| Documentation | Audit reports, training logs, supplier relations records | Lab analysis of samples |

| Compliance Checks | Social compliance, environmental compliance like ISO 14001, working conditions | Product audit specifics like defects |

| Tools Used | Audit software, digital audits, checklists | Sampling equipment, quality labs |

This table clarifies scope for third-party auditors planning a GMP audit. It promotes continuous improvement by targeting root causes in the supply chain. For instance, in a GMP audit, focus stays on hygiene protocols, not batch testing.

Who needs it: Businesses and situations

High-volume buyers like Walmart, Disney, or Target conduct factory audits before major orders. These companies use audits to verify supplier evaluation and ensure factories meet quality control standards. This step reduces risks in the supply chain.

Importers facing customer requirements rely on quality audits and social compliance checks. For example, apparel brands audit for labor standards and working conditions. Such audits prevent disruptions from non-conformances.

| Situation | Pros of Auditing | Cons of Auditing |

|---|---|---|

| High-volume purchasing | Confirms production capabilities and product quality | Requires time and third-party auditors like those from Sedex |

| New supplier onboarding | Identifies process audit gaps early | Upfront costs for audit checklists |

| Regulatory compliance | Meets ISO 9001 or SMETA needs | Follow-up for corrective actions |

Brands pursuing continuous improvement schedule regular system audits. Electronics manufacturers, for instance, check QMS standards to align with operational efficiency. This builds strong supplier relations.

Companies in regulated sectors need GMP audits, ISO 13485 for medical devices, AS9100 for aerospace, or environmental audits. Food producers like Nissin Food verify production process hygiene, while others ensure ISO 14001 compliance. Audits support risk management across scenarios.

4. Quality Audit

Don’t let defects slip through. Common mistakes like skipping on-site product checks lead to recalls. A quality audit catches these early, much like a GMP audit.

Quality audit inspects products against specs. It inspects processes too.

Facilities must meet quality standards. They must meet operational requirements. This identifies production gaps. It ensures consistent quality.

Quality audits include sample inspections and reviews of defect rates. Auditors examine finished goods or in-process items for flaws. This helps spot issues before shipment.

- Visual checks for surface defects like scratches or color mismatches.

- Functional tests, such as measuring dimensions on electronics components.

- Reviewing quality control records for patterns in non-conformances.

Unlike other audits, it excludes management systems like ISO 9001. Focus stays on tangible product output. Consumer goods brands with precise specs, like apparel or toys, need this most.

Avoid pitfalls such as trusting supplier self-reports, which often overlook real issues. Use third-party auditors for objective supplier evaluation. Plan follow-up audits to confirm corrective actions.

Defines what and why important

Factory audits protect supply chain integrity. They reduce risks. Buyers verify supplier compliance.

Audits check customer requirements. They check regulatory standards. Regular audits drive improvement. They strengthen supplier relations.

Without proper audits, issues like non-conformances can lead to costly recalls or delays. They support quality management systems like ISO 9001 by documenting findings in audit reports. Experts recommend them for maintaining operational efficiency across global manufacturing.

Common pitfalls undermine audit effectiveness. Here are the top 3 mistakes to avoid:

- Ignoring audit checklists and relying on memory, which misses key SOPs and leads to incomplete assessments.

- Failing to plan follow-up audits, allowing non-conformances to persist without corrective actions.

- Overlooking Gemba Walks in favor of paperwork, missing real-time insights into working conditions and production capabilities.

Includes what and excludes what

Product sampling and testing; no deep system audits. This type of factory audit focuses on immediate product quality checks, such as inspecting samples from the production process for defects or compliance with customer requirements. Auditors use audit checklists to verify specifications without probing into broader operations.

To prevent issues, implement pre-audit preparation by training staff on sampling protocols and maintaining clear SOPs for quality control. This approach ensures supplier evaluation stays targeted, catching visible non-conformances early. Regular use supports continuous improvement in product standards.

Exclusions keep the audit process efficient, avoiding in-depth reviews of quality management systems like ISO 9001 or process flows. Instead, prioritize corrective actions for sampled items, such as reworking faulty batches. This method suits quick third-party auditors assessing operational efficiency.

For best results, combine with digital audits using audit software to log findings instantly. Schedule follow-up audits to track fixes, strengthening supplier relations and risk management. Experts recommend this for high-volume supply chain checks without overwhelming resources.

Who needs it: Businesses and situations

Pre-shipment audits suit apparel and electronics businesses facing high return risks. These audits check product quality right before shipping to spot defects early. Companies avoid costly returns by verifying stitching flaws in garments or faulty circuits in devices.

Importers dealing with new suppliers on platforms like Alibaba benefit from factory audits during supplier evaluation. Risks like inconsistent production processes can lead to delays or failures. Experts recommend these checks to confirm capability verification and adherence to customer requirements.

Brands in regulated sectors need social compliance audits such as SA8000 or SMETA from Social Accountability International or Sedex. They address risks of poor working conditions and International Labour Organization labor standards violations. This protects supplier relations and meets ethical audit demands from global markets like Walmart, Disney, and Target.

Manufacturers pursuing continuous improvement use process audits or Gemba Walks for operational efficiency. High-risk situations include supply chain disruptions from non-conformances. Third-party auditors help implement corrective actions and follow-up audits effectively.

Quality Management System Audit

Pro tip: Start with document reviews before floor walks to maximize QMS Audit efficiency, as QCadvisor auditors do in 24h. This quality management system audit checks compliance with established standards like ISO 9001. It focuses on procedures and documentation for continuous improvement.

A system audit verifies that the factory’s quality management processes align with QMS standards. Auditors review SOPs, training records, and corrective actions logs. This step ensures the production process supports consistent product quality.

Key elements include ISO 9001 documents and internal procedures, but it excludes physical product inspections. Use audit checklists to cross-verify SOPs against actual practices during Gemba Walks. This hack reveals gaps in supplier evaluation and operational efficiency.

- Examine non-conformances from past audits for follow-up.

- Check customer requirements integration into procedures.

- Assess risk management in the supply chain.

- Verify third-party auditors records for traceability.

Certified suppliers and regulated industries in medical devices (ISO 13485), aerospace (AS9100), or food like Nissin Food need this factory audit most. It drives Lean Manufacturing principles and prepares for follow-up audits. Experts recommend digital tools like GoAudits for real-time audit reports.

Defines what and why important

Evaluates formal quality systems like ISO 9001 for standardized processes. A factory audit is a structured review of a manufacturer’s operations, facilities, and compliance. It checks everything from production processes to worker safety.

These audits matter because they spot risks early in supplier evaluation. They ensure product quality meets customer requirements and regulatory standards. Poor audits can lead to recalls or supply chain disruptions.

Experts recommend using audit checklists for consistency. Conduct Gemba Walks to observe real-time work. Always document non-conformances with photos for clear audit reports.

Factory audits, including GMP variants, drive continuous improvement through corrective actions. They build trust in supplier relations and boost operational efficiency. Regular checks align with ISO 9001.

- Tip 1: Train auditors on SOPs before starting to avoid bias.

- Tip 2: Use GoAudits ( Capterra rated) for digital audits and instant data.

- Tip 3: Schedule follow-up audits to verify fixes on non-conformances.

- Tip 4: Involve third-party auditors for objective capability verification.

- Tip 5: Focus on high-risk areas like working conditions in social compliance reviews.

Includes what and excludes what

Factory audits that focus on documentation include policies and training records but skip hands-on production. Auditors review written materials like quality manuals, SOPs, and employee certification logs. This approach verifies system compliance without disrupting the production process.

Key inclusions cover audit checklists. They target QMS standards like ISO 9001. They also cover social compliance like SA8000.

Auditors check records. They review corrective actions and risk management. They evaluate suppliers like Factored Quality. Exclusions avoid Gemba Walk on the shop floor.

For quick verification, look for dated signatures on training logs and cross-reference with employee IDs.

Spot-check non-conformances from prior reports. Confirm follow-up audits occurred. This ensures efficiency without full production audits.

Consider a process audit example. Confirm ISO 14001 policies match waste logs. Ignore live machine operations. Use digital audit software for fast scans. This balances thoroughness and minimal downtime.

Documentation Deep Dive

System audits prioritize paperwork. They focus on quality control procedures. They ensure regulatory compliance. Review reports for continuous improvement. Skip inventory counts to stay focused.

Scan revision dates on SOPs. Verify updates against customer needs.

Check labor records for SMETA or C-TPAT alignment. Consider HTS codes for customs. This reveals supply chain gaps fast.

Quick Verification Tricks

Examine training records. Match attendance sheets to working conditions logs. Verify capabilities in documents. Avoid testing machines. Auditors flag mismatches for corrections.

Use checklists to confirm GMP audit or environmental compliance files align with Lean Manufacturing principles. A fast check: Verify third-party auditors’ stamps on security audit sections. This streamlines supplier relations evaluation.

Who needs it: Businesses and situations

Medical device firms need audits. They require ISO 13485 or GMP compliance. Audits verify regulatory standards.

Production meets QMS standards. Audits minimize patient safety risks. Experts recommend regular GMP audits for consistent product quality.

Apparel and electronics manufacturers facing social compliance demands benefit from SA8000 or SMETA audits. These evaluate working conditions, labor standards, and ethical practices in the supply chain. Use audit checklists to document non-conformances and plan corrective actions.

Food and beverage companies use process audits to check hygiene and operational efficiency during production. Automotive suppliers rely on system audits for ISO 9001 alignment and supplier evaluation. Tailor audit reports to highlight gaps in SOPs and drive continuous improvement.

- Importers conducting product audits to confirm specifications before shipment.

- Brands performing environmental audits under ISO 14001 for sustainability goals.

- Logistics firms needing C-TPAT audits or security audits for risk management.

- Tech companies verifying production capabilities through capability audits or Gemba Walk s.

Structural Audit

A garment factory collapsed. It exposed weak structures. Our Structural Audit assesses building integrity. It prevents disasters. It protects workers.

Structural Audits act as a building and facility safety check. They evaluate risks like unstable foundations or poor load-bearing walls. Experts recommend them for labor-intensive factories in older buildings to ensure worker protection.

Key areas cover fire safety. They include alarms and exits. Auditors check electrical systems too.

Inspect roofing, walls, and foundations. Use audit checklists. This differs from production metrics. It excludes ISO 9001 quality.

- Verify emergency exits meet regulatory standards.

- Check wiring for fire hazards in high-use areas.

- Assess structural supports in multi-story facilities.

- Review maintenance logs for ongoing risk management.

Factories with heavy machinery benefit most from these audits. They support social compliance by addressing working conditions. Follow-up with corrective actions ensures long-term operational efficiency.

Defines what and why important

It inspects physical infrastructure. It ensures ISO 14001 safety compliance. Factory audits review operations. They check processes and conditions. They ensure regulatory adherence.

These audits identify risks in production processes and working conditions. For example, during a SMETA audit, auditors check fire exits and machine guards. This prevents accidents and supports continuous improvement.

Factory audits matter for supplier evaluation and supply chain reliability. They verify quality control measures, like proper SOPs for handling materials. Companies avoid costly recalls by addressing non-conformances early.

Experts recommend regular audits to meet customer requirements and standards like ISO 9001. In one case, a textile factory passed a SA8000 ethical audit after fixing overtime violations. This strengthened supplier relations and boosted operational efficiency.

Includes what and excludes what

Factory audits typically include checks on building codes and exits, but exclude detailed quality processes like AS9100. Auditors verify fire safety exits, structural integrity, and emergency lighting to ensure worker safety. This focus prevents hazards like blocked pathways during evacuations.

For example, in a textile factory audit, inspectors confirmed wide, unobstructed exits compliant with local codes. They noted issues like locked secondary doors, requiring immediate corrective actions. Such findings highlight risks in non-compliance during emergencies.

Exclusions often cover in-depth product audits or process audits, which test manufacturing steps separately. A social compliance audit might skip quality control metrics, leaving those for a dedicated quality audit. This separation keeps audits targeted and efficient.

Understanding these boundaries aids supplier evaluation. Factories prepare using audit checklists for included areas like working conditions, while scheduling follow-up system audits for excluded ones. Clear scopes improve operational efficiency and risk management.

Who needs it: Businesses and situations

Apparel brands post Rana Plaza-like events often seek factory audits to ensure worker safety and ethical practices. These audits help rebuild trust with consumers and meet social compliance standards like SA8000 or SMETA. One brand conducted regular ethical audits after such incidents, identifying hazards early and improving working conditions.

Importers of electronics or toys rely on quality audits and product audits to verify product quality before shipping. A toy manufacturer used third-party auditors to check for choking risks, avoiding recalls and strengthening supplier relations. This approach aligns with customer requirements and regulatory standards.

Food and pharmaceutical companies need GMP audits or process audits to maintain hygiene in the production process. After a contamination scare, one processor implemented audit checklists and corrective actions, boosting operational efficiency. Experts recommend these for high-risk sectors focused on quality control.

- Retailers expanding supply chains use supplier evaluation via capability audits to assess production capabilities.

- Automotive firms perform system audits for ISO 9001 and QMS standards, ensuring continuous improvement.

- Brands prioritizing sustainability conduct environmental audits under ISO 14001 to check environmental compliance.

- Logistics providers opt for C-TPAT audits or security audits to manage risk management in global trade.

Which Factory Audit Type Fits Your Needs?

Beyond basics, audits like C-TPAT audit dive into chain-of-custody protocols using source standards. These connect to broader factory audit types where quality management systems feed into quality audits. For instance, a strong QMS under ISO 9001 supports process audits by tracking non-conformances.

Consider risk management in your supply chain to choose wisely. High-risk suppliers need security audits alongside product audits for complete coverage. System audits then verify if corrective actions from initial findings improve operational efficiency.

A decision framework starts with source criteria like risk level and customer requirements. Low-risk cases suit supplier evaluations, while regulatory standards demand full GMP audits or environmental checks. Map interconnections, such as how social compliance informs ethical audits.

Experts recommend layering audits for continuous improvement. Begin with a capability audit, follow with process audits, and end with follow-up audits. This ensures product quality and supplier relations align with your needs.

How does QCadvisor, praised on Capterra, deliver these audits in 24h across Asia?

QCadvisor leverages local auditor networks for same-day factory visits and digital reporting. This enables rapid factory audits from China to Vietnam using third-party auditors trained in audit checklists. Reports arrive quickly for timely decisions.

Key advantages include rapid response times that cut delays in supplier evaluation. Their GoAudits software streamlines data capture during Gemba Walks or virtual checks. This boosts quality control without long waits.

- GoAudits software for real-time checklists and photo evidence during production process reviews.

- Follow-up audits scheduled instantly to address non-conformances from initial findings.

- Network of auditors ensures coverage for audit reports on QMS standards or Lean Manufacturing practices.

Clients use this for quick insights into working conditions or production capabilities. It fits high-volume manufacturing audit needs across Asia’s supply chain.

What situations demand Security/C-TPAT, Social, Ethical, or Environmental Audits?

Myth: Social audits are just PR. Actually, SA8000/SMETA from Social Accountability International verify International Labour Organization labor standards against child labor risks. Use them when retailer codes like Walmart, Disney, or Target require social compliance checks on working conditions.

Debunk another myth: Environmental audits are unnecessary in Asia. ISO 14001 audits ensure compliance amid growing regulations for waste and emissions. They pair with ethical audits for full supplier relations oversight.

C-TPAT audits fit US imports facing security risks for HTS codes. They demand chain-of-custody reviews beyond basic security audits. Sedex protocols help retailers meet ethical standards in high-risk factories.

- Myth busted: C-TPAT is optional. It protects against supply chain threats for US-bound goods.

- Social audits prevent legal issues from poor labor standards.

- Environmental audits like those from Nissin Food or platforms like Alibaba support sustainability goals in production processes.

- Ethical audits reveal hidden issues like forced labor via SMETA checklists, ensuring Factored Quality.

Why choose Supplier Assessment or Virtual Walk Audit for quick insights?

Resource roundup: Tools like GoAudits enable Virtual Walk Audits for remote SOP checks without travel. These suit capability verification in supplier assessments, incorporating Gemba Walk techniques. They verify production capabilities fast.

Use supplier assessments for initial supplier evaluation before full factory audits. Virtual options review audit processes via video for QMS standards or regulatory standards like ISO 14001. This saves time on low-risk partners.

- Audit software like GoAudits for digital audits and instant sharing of findings.

- Protocols for quick checks on SOPs, non-conformances, Lean Manufacturing principles, and operational efficiency.

- Combine with Gemba Walk videos for remote process audit insights.

Ideal for ongoing continuous improvement without disrupting supply chain flow. They provide actionable data on product quality and customer requirements efficiently.

Frequently Asked Questions

What are the different types of factory audits, including HTS classification checks?

Factory audits are essential for ensuring supplier reliability and compliance. The main types include Factory Verification Audit, Technical Audit, Capacity Audit, Quality Audit, Quality Management System Audit, Structural Audit, Security/C-TPAT Audit, Social Compliance Audit like SA8000 and SMETA, Ethical Audit, Environmental Audit, Supplier Assessment, GMP audit, and Virtual Walk Audit. At QCadvisor, we arrange factory visits and thorough supplier evaluations within 24 hours in China or elsewhere in Asia.

What is a Factory Verification Audit and what are the different types of factory audits it relates to?

A Factory Verification Audit confirms the existence, operational status, and basic capabilities of a factory, which is crucial for mitigating risks when sourcing from new or unverified suppliers. It prevents fraud and ensures you’re dealing with a legitimate operation.

- Included: Factory location verification, operational status check, basic equipment review, workforce presence, and initial production line observation.

- Not included: In-depth quality testing, detailed financial audits, or comprehensive compliance checks like social or environmental standards.

- Who needs it: Importers and brands new to a supplier; e-commerce businesses; situations involving high-risk new vendors or online marketplaces.

QCadvisor offers fast Factory Verification Audits. They are part of our supplier evaluation services. They suit sourcing via platforms like Alibaba. We have top ratings on Capterra and Factored Quality.

How does a Technical Audit differ from other types of factory audits?

A Technical Audit evaluates technical capabilities. It checks machinery and processes. This ensures suppliers meet product specs. It maintains consistent quality.

- Included: Machinery condition and calibration, technical staff competency, process flow analysis, R&D capabilities.

- Not included: Worker welfare checks, environmental impact assessments, or broad financial stability reviews.

- Who needs it: Manufacturers of complex products like electronics or machinery; businesses scaling production; tech-heavy industries.

Use QCadvisor’s factory audits. Get expert technical evaluations. Receive them quickly.

What are the different types of factory audits like Capacity Audit?

A Capacity Audit assesses production capacity. It checks scalability. This avoids bottlenecks. It ensures timely delivery during peak demands.

- Included: Production line throughput measurement, workforce capacity, storage and logistics review, peak vs. normal output analysis.

- Not included: Quality control processes, ethical labor practices, or security protocols.

- Who needs it: Retailers with seasonal demands; growing brands; businesses planning large orders or expansions.

QCadvisor provides Capacity Audits. We deliver them within 24 hours. They cover Asia-based factories.

In the context of different types of factory audits, what is a Quality Audit?

A Quality Audit inspects QC systems. It checks processes. This minimizes defects. It ensures products meet standards and protects brand reputation.

- Included: QC procedures, testing equipment, defect logging, incoming material checks.

- Not included: Structural safety, social compliance, or environmental regulations.

- Who needs it: Consumer goods brands; high-volume importers; situations with past quality issues.

Benefit from QCadvisor’s Quality Audits. They are thorough. Find them in our factory audit services.

What are the different types of factory audits including Quality Management System Audit?

A Quality Management System Audit verifies standards. These include ISO 9001, ISO 13485, and AS9100. It ensures certified processes. They guarantee reliability and improvement.

- Included: Documentation review, internal audit processes, corrective action systems, management commitment.

- Not included: Physical structural checks, security measures, or ethical sourcing evaluations.

- Who needs it: Companies requiring ISO compliance; automotive or medical device sectors; businesses in regulated industries.

QCadvisor arranges Quality Management System Audits. We do this efficiently across Asia. They align with Social Accountability International. They follow International Labour Organization guidelines.

Among different types of factory audits, explain Structural Audit and Sedex?

A Structural Audit examines building safety. It checks fire protection and infrastructure. This supports worker safety. It ensures legal compliance and reduces risks.

- Included: Building integrity, electrical systems, fire exits, machinery guards.

- Not included: Production quality, capacity calculations, or social audits.

- Who needs it: Brands prioritizing safety; apparel and toy manufacturers; post-disaster or renovation scenarios.

Ensure safety with QCadvisor’s Structural Audits. Use them in factory inspections. Brands trust us. These include Walmart, Disney, Target, and Nissin Food.