During Production Inspection

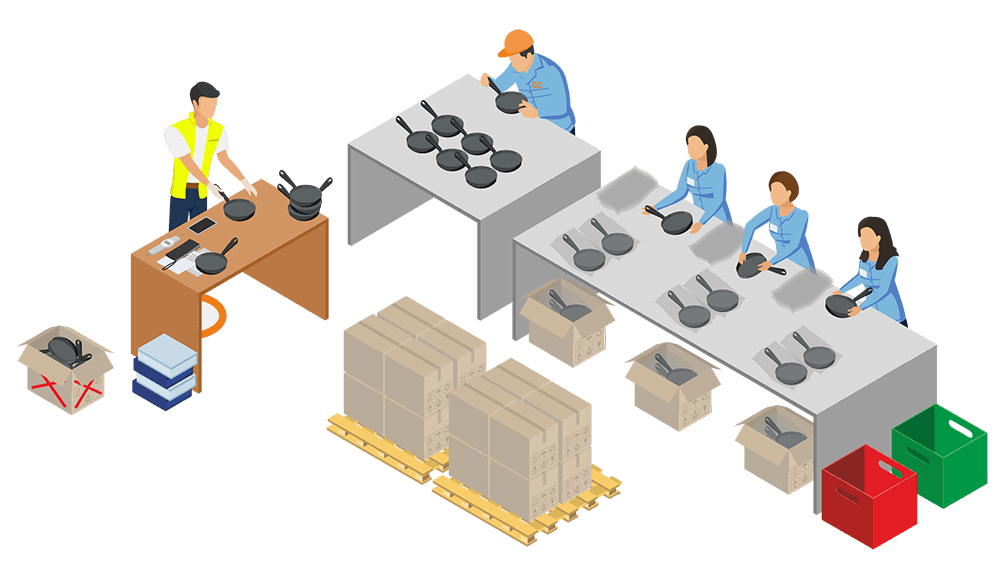

During Production Inspection (DPI), sometimes called DUPRO or an in-process quality control inspection, is the safety net that keeps your production cycle on track. Performed while 20-50 % of the order is underway, DPI lets QCADVISOR’s inspectors step onto the factory floor, verify workmanship, and correct quality issues before the goods are fully packed.

At QCADVISOR we combine seasoned quality control inspectors, data-driven checklists, and real-time reporting to protect your brand reputation throughout the production process. Our team coordinates directly with your supplier, applies industry-standard sampling (ISO 2859-1 AQL), and delivers an illustrated inspection report the same day—so you can decide, follow up, and keep the production schedule moving.

Key benefits at a glance

- Early risk detection that slashes rework and production costs

- Live visibility into production progress, quantities and compliance data

- Actionable inspection report within hours, not days

- Independent assurance that safeguards shipments and customer satisfaction

How Does QCADVISOR perform a During Production Inspection?

Our process begins with a digital brief that transforms your product specifications into an on-site inspection checklist. An expert inspector, selected for your product category, visits the factory once the agreed production threshold is reached.

During the visit we systematically check:

All findings feed straight into our cloud platform, giving you traceable data and clear next-step recommendations.

What are the steps of a During Production Check (DUPRO)

- Initiation & planning – agree on scope, checklist and inspection window

- Sampling method selection – determine lot size and AQL levels

- On-site inspection – execute checks, tests and measurements

- Documentation & reporting – compile results, photos and defect analysis

- Corrective actions & follow-up – supplier fixes issues, QCADVISOR re-verifies if required

What is included in the During Production Inspection report?

Your illustrated PDF report—delivered within a few hours of inspection—covers:

- Executive summary with pass/fail status and production progress data

- Detailed defect breakdown by severity and defect code

- Sample size, AQL tables and statistical results

- Product specification checks: dimensions, colors, materials, workmanship notes

- Functional and safety test outcomes with measurement readings

- Packaging, labeling and shipping-mark verification photos

- Factory conditions, process observations and risk alerts

- Actionable recommendations and required follow-up steps

- Timestamped, geo-tagged photo gallery for full transparency

This report becomes a living document you can pass to suppliers, logistics teams and stakeholders to maintain control across the supply chain.

When should you perform a DUPRO?

Schedule the inspection when roughly 20 %–50 % of the mass production stage is complete: enough finished units for meaningful random sampling, yet early enough to implement corrective action without derailing the production schedule. Typically, a DUPRO follows a pre-production inspection (raw materials and first-off prototype checks) and precedes the pre-shipment inspection that validates 80 %+ packed goods. For continuous or high-volume orders, multiple DUPROs may be staged to keep quality consistent throughout the production cycle.

Why Work with QCADVISOR?

Because we treat every project as mission-critical from the first production check to final shipment.

Partner advantages

- Specialized focus on quality control—no sourcing, no conflicts of interest

- 48-hour deployment across major Asian manufacturing hubs

- Inspection team matched to your product expertise and language

- Cloud-based dashboard that tracks inspection data, trends and supplier performance

With 95 % of clients recommending QCADVISOR, you gain a proactive quality partner committed to defect-free product delivery and sustained customer satisfaction.

How to schedule a During Production Inspection with QCADVISOR?

- Book online —log in to the QCADVISOR platform and create your inspection project at least 48 hours in advance.

- Confirm quotation —we review your brief and send a transparent, all-inclusive quote.

- Supplier coordination —your factory confirms the inspection date via our system or email.

- Inspection day —our inspector arrives on site, performs the DPI and uploads data in real time.

- Receive your report —check your inbox or dashboard for the full inspection report the same day and decide on follow-up actions.

Ready to add a safety net to your production process? Book your During Production Inspection with QCADVISOR today and keep your goods—and your brand—on the right track.

Trusted Worldwide

We inspect products for the world-leading brands and marketplaces.

Join the league of successful brands who never compromise on Quality.

With QCADVISOR, embrace the advanced techniques that set market leaders apart. Are you ready to level up?