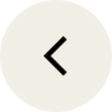

Manufacturing machinery plays a crucial role in various industries, enabling efficient production processes. Quality and user experience are paramount when sourcing these machines. Asia, particularly countries like China, Japan, and South Korea, is known for manufacturing machinery. However, there are potential quality risks associated with sourcing from Asia. Thorough Quality Control and Due Diligence are essential to mitigate these risks. Buyers must prioritize inspecting the manufacturing process, materials used, and adherence to safety standards. By ensuring rigorous quality checks, businesses can confidently source manufacturing machinery from Asia while maintaining high standards and delivering exceptional user experiences.