This year despite the global slowdown caused by Covid 19, Chinese factories in various industries are still getting busy and risks of rushed productions and quality issues are still high.

The “rush” starts few weeks before February (around early December) depending on the industry you are in and orders lead time. All the factories start speeding up to complete their orders on time before their workers desert the production lines.

The Chinese New Year (CNY) has a direct impact on deadlines and time to market. This special and busy period also turns out to be one of the most critical for your products quality. Complaints rate peak for bad quality orders is usually around March-April (When all pre-CNY orders arrive at destination).

To avoid horror stories like delayed shipments or quality disaster on your order keep in mind these 3 basic rules:

RULE 1: ORDER ON TIME FOR A SUCCESSFUL PRODUCTION DURING THE CNY

Ordering on time and without taking unnecessary risks cannot be done if you don’t know the main milestones of your production and how factories work the days before CNY holidays.

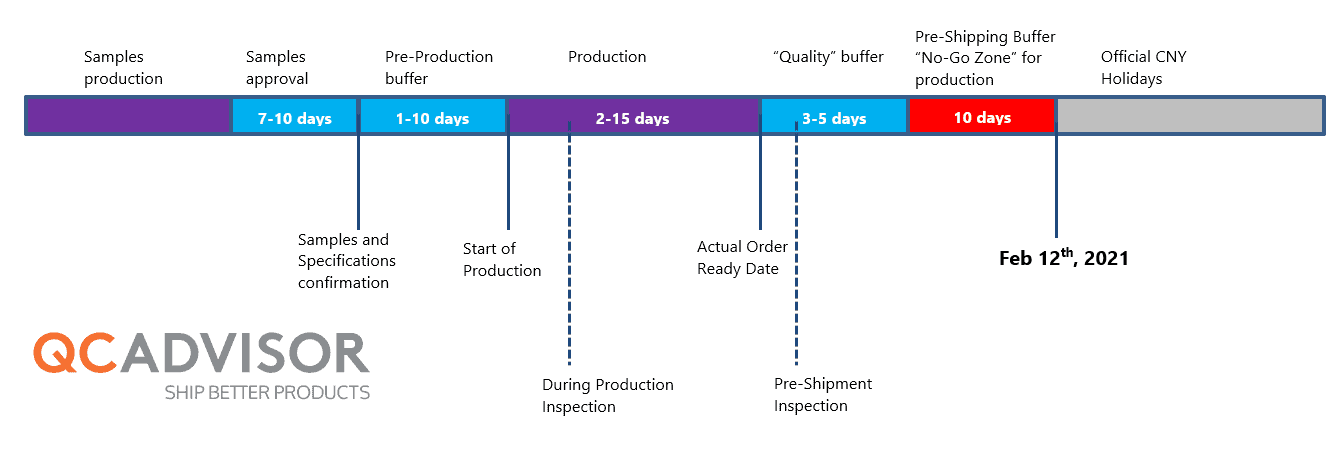

In 2021, the Chinese New Year eve is expected on Feb 12th. The official holidays start from Feb 11th and end on Feb 17th.

Suppliers start refusing pre-CNY orders early December. It is also common to see workers leaving 1 week to 2 weeks before the official holidays heading to their hometown. China having about 100 million people traveling to visit their family during this period, travelers like to take some precautions.

Below the milestone chart to help you decide when you can start production without taking risks. As production time is different for every industry and project (If you are printing 3000 sets of postcards in Dongguan of manufacturing 50.000 pouch bags in Henan), the chart focuses on common steps (samples validation, production start date, order ready date, inspections, and shipment).

Grey areas can be adjusted depending on your specific order production time.

The 10 days before the CNY are an absolute NO-GO Zone for production.

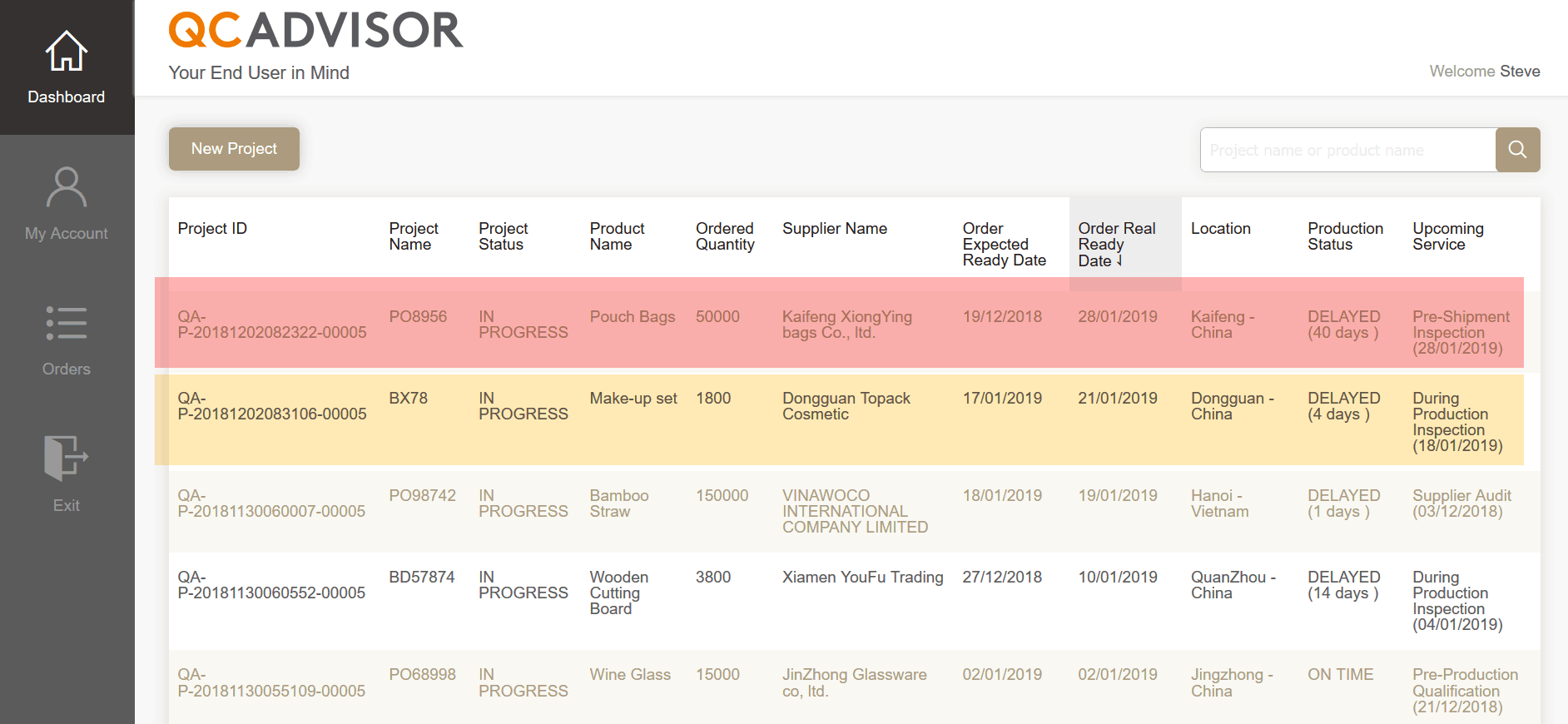

Below from our QCADVISOR Online Booking system, that also allows following orders production status, you can see that the order highlighted in red is at high risk of not being shipped on time or being manufactured “too fast” with a high risk of quality issues.

The order highlighted in orange might also present risks, that are wisely reduced by having a During Production Inspection planned few days before the expected order ready date.

RULE 2: PREPARE THE SHIPPING EARLY ON

Consider yourself safe only when your order has left China.

S… can still happen even your order is 100% produced. The most common post-production issue is a delay with China customs procedures.

At QCADVISOR we generally advise our clients to prepare all necessary documents to export their products from China early on. Even you are using a third party to handle your supply chain, it is wise to double check with them if all documents are ready before production. Goods can be delayed or blocked by Chinese customs because one crucial certificate or authorization is missing.

Example: You are manufacturing a product for a famous brand and their logo is on the product (let’s say an umbrella for Coca-Cola). The day the goods are supposed to be shipped, our friends from Chinese customs block the container because you don’t have a valid authorization from Coca-Cola that you can manufacture this product with their logo on it and that you are not infringing any IP right.

It is Friday night and the certificate can only be ready the next Monday (you know how big corporations work). Moreover, and because it’s the week before CNY all vessels are overbooked…

RULE 3: DON’T SACRIFICE QUALITY

After 12 years working with hundreds of customers from different industries and countries, I have observed the most successful importers all have one thing in common: No shortcuts when it comes to production and sourcing from China.

Trying to ship on time without taking enough care about the quality is a recipe for disaster. Never sacrifice or skip steps of your usual Quality Management and QC process:

- Confidence that the factory can make your product as per your requirements (Can be checked during Factory audit and through product/prototype qualification)

- Confidence that they can produce the quantity required on time with the same level of quality (Factory audit, Pre-production Qualification and During Production Inspection)

- Confidence that all your order is produced with the required level of quality and is within the Acceptable Quality Limits. (Pre-Shipment Inspection, Container Loading Inspection)

On top of that always keep 3-5 days “buffer” in case defects are found during the inspection, to allow the factory to rework/replace defective items and ship on time.

Factories, even those you work with frequently and know your product(s), will have to take shortcuts at some point and give less attention to your order (with higher risks of quality issues) to complete all their production planning before the “fateful date”.

To sum up: Key to successful production during the CNY in China?

- Accurate assessment of your production time to allow you to place your order early enough.

- Allowing enough time to manage your sourcing and QC process shortcut-free.

Sourcing from China and wondering how to better control your Production and Quality? Email us at hello@qcadvisor.com.