Pre-Production samples (PPS) are common in the sourcing process. The main aim of a Pre-Production sample is to agree on a level of quality and the specifications for your products to launch the production according to the same and exact standards (Shape, Color, Material and other specifications).

Important aspects about PPS

- The PPS is finalized BEFORE the production starts.

- The PPS is made during the prototyping phase and is the last prototype you agree on with your supplier.

- Made by skilled workers or production team members.

- May be relatively costly to manufacture one single PPS , raw material and accessories are often more expensive for low quantities. Factories sometimes use high prices to discard less serious buyers.

- PPS can also be called Golden Sample, Approval sample or Reference sample.

Benefit 1: Proving The Factory Is Capable

If you are working for the first time with a supplier, the approval sample is part of the supplier selection process. After the supplier audit, it’s the last chance to decide if you really want to move forward with your supplier.

This helps you ensure your supplier understands your needs and can manufacture your product correctly.

Manufacturing an approval sample is an excellent way to prove the suppliers ability to produce your order without unnecessary quality issues and delays.

Benefit 2: Qualify your design and specifications

The final prototype(s) is supposed to meet your specifications and client’s need(s) which will be used for testing. This is known as design qualification.

First Part: Regulatory Requirements:

All aspects of the product related to regulatory requirements for the destination country must be tested and approved.

It is common to see buyers/suppliers perform tests on production samples and receive results while products are being shipped. This strategy might help you save a few days and fees, but is risky and could have your order refused at customs.

Second Part: Functionality and Cosmetic.

Functionality problems can heavily impact your brand image. Successful brands always perform thorough testing on their products’ functionality before the final design. The only way to check these possible issues, is to have your final product tested.

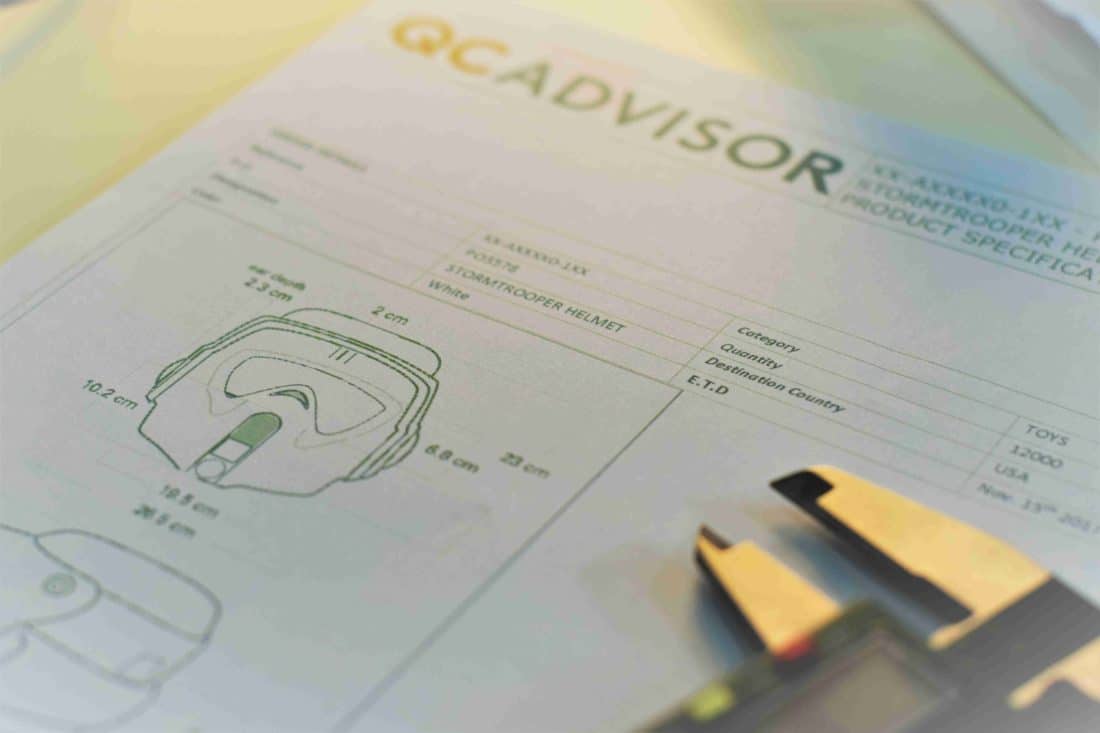

At QCADVISOR we also try to go beyond the existing specifications and are always considering the end user in mind when creating Inspection Checklists for customized products.

Benefit 3: Detecting Costly Details

Costly details can be missed by your supplier or forgotten when writing down product specifications: Labels on the wrong side, un-scannable barcodes, slogan misspelling or missing warning messages.

An approval sample should ideally include all the packaging, labeling/marking and accessories. This will help you ensure that everything is ready before Mass production.

Benefit 4: Your Best Contract

The approval sample is a very efficient way to protect yourself during production. Material finish can sometimes be extremely difficult to describe in a written document. Factories tend to save cost by slightly downgrading raw materials for production. A signed approved sample at the factory can help protect you from these issues.

Benefit 5: Avoid Misunderstandings With All Parties

As a 3PQC professional witnessing different types of practices everyday between importers and chinese suppliers, I can confirm that approval samples are the best way to avoid misunderstandings when it comes to product requirements. Clients we serve who have an approval sample for every order experience a much lower rate of “misunderstandings.” We also see higher rates of pass inspections before shipment.

TIPS

It is recommended to get 3 PP samples, one for you, one for the factory, and one for the Inspection company or your QC team.

Are you making PP sample for every of your orders in China? QCADVISOR team can help you qualify and manage your PP sample locally with your suppliers, saving time and money on a critical step of your sourcing process.